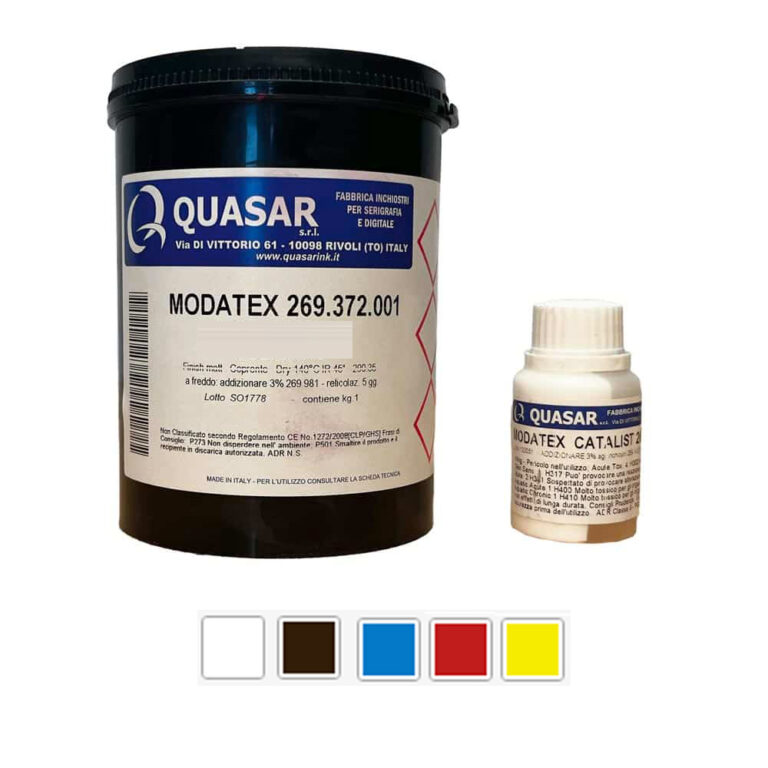

Modatex Quasar. Professional water-based ink

Please note: a catalyst bottle is included, no need to buy it separately.

Drying with hot air speeds up the drying process and improves washfastness.

It is recommended to use the hardener only in the portion of the ink that is used. In any case, the hardener does not spoil the ink in which it has been placed, but loses its hardening effect after 200 hours (approx. 1 week), thus requiring an addition to the ink.

Modatex Quasar ink is single-colour when used with a hot air oven.

It is characterised by a soft hand even on very thick layers.

Modatex Quasar can be used on mixed and synthetic fabrics and has great elasticity.

It is used on cotton fabrics, which are also fairly elastic.

Its resistance to washing is achieved by perfect oven drying.

Translated with www.DeepL.com/Translator (free version)