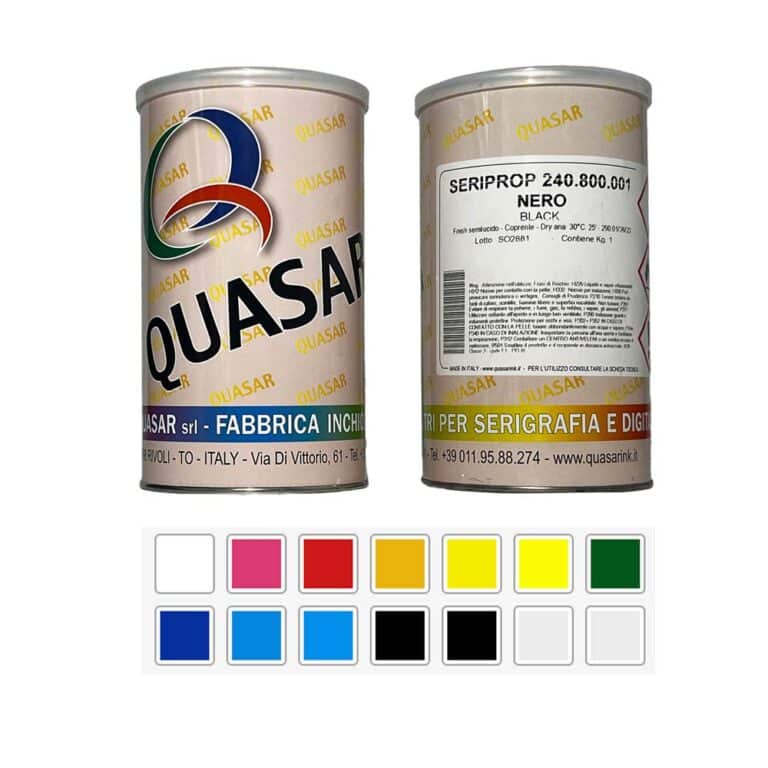

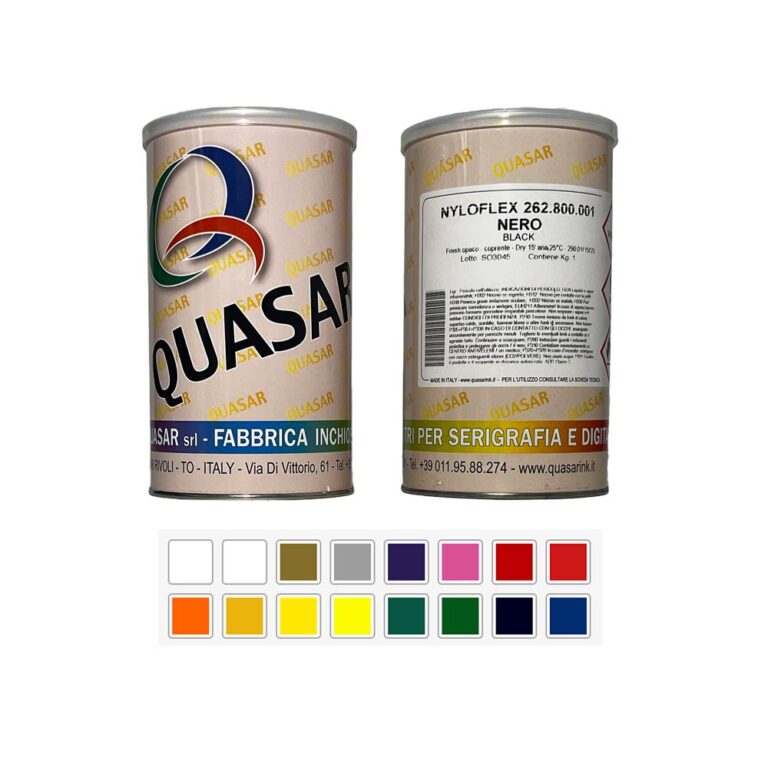

Different types of ink for printing with the tampography technique. Tampography ink Tampography is a printing technique that requires the use of specific type screen printing inks, and that is why on CPLFabbrika we offer you a wide and varied choice of inks for pad printing, available with excellent offers and which you can therefore buy with a considerable savings. In the catalog there are the different varieties of pad printing ink most used by both professionals and simple enthusiasts, starting from the single-component type, particularly suitable for printing on plastic-type surfaces such as PVC and PET, but also perfect for printing on wood, with the possibility of increasing the hold on the most difficult surfaces with the help of a catalyst. If, on the other hand, you are looking for pad printing inks that allow customization on glass, metal and ceramic, then you can opt for the two-component type, which in addition to being flexible and covering has excellent heat resistance and dries quickly. The classic pad printing inks naturally need the right accessories to be used at their best, and here in the catalog you can find different pad printing clichés, to be engraved with the desired image which will then be covered with the chosen pad printing ink. At this point it becomes essential to have one or more printing pads, on which the image is then collected directly from the cliché, to then be imprinted on the surface to be customized with the correct amount of ink for pad printing. With our pad printing ink you can give your personal touch not only to rigid surfaces, but also to fabrics of various kinds, with the creation of personalized clothing with high quality and precision prints, above all durable and resistant. Enter CPLFabbrika now and discover the online sale of quality pad printing ink at a discounted price, a unique offer ideal to satisfy your every need.

Inks for Tampography

Technical Assistance

Write us: INFO@CPLFABBRIKA.COM

Write us +39 347 5804961

Upload Files

Click here

from 9,50 €+ tax

11,59 € tax incl.

from 20,00 €+ tax

24,40 € tax incl.

from 30,00 €+ tax

36,60 € tax incl.

from 25,00 €+ tax

30,50 € tax incl.

from 26,00 €+ tax

31,72 € tax incl.

10,50 €+ tax

12,81 € tax incl.

18,50 €+ tax

22,57 € tax incl.

Technical Assistance

Write us: INFO@CPLFABBRIKA.COM

Write us +39 347 5804961

Upload Files

Click here