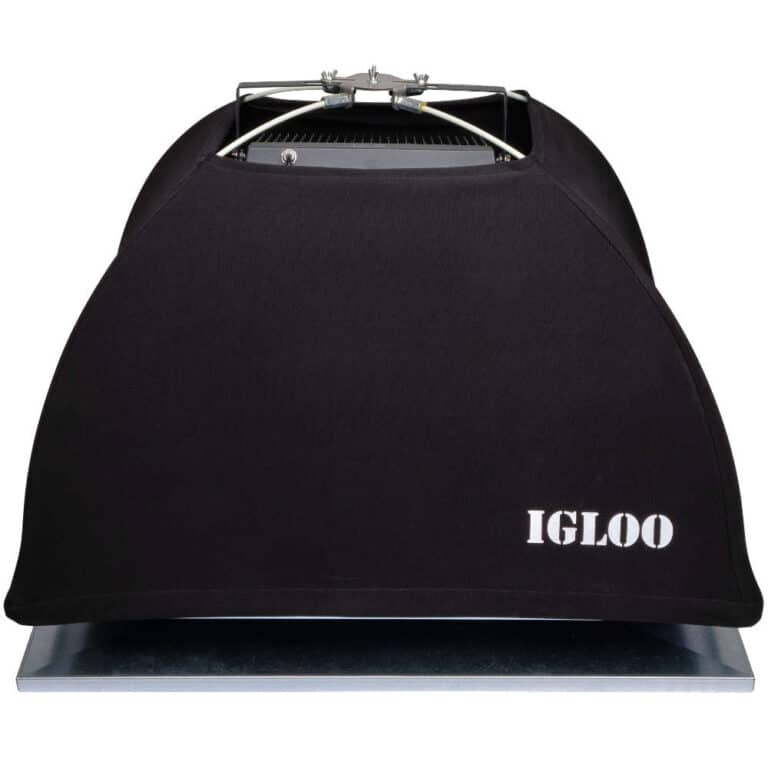

Space-saving washout booth for screen printing screens: just 50 cm deep and 100 cm wide and can comfortably accommodate screens up to 80×90 cm in size.

Booth dimensions: 50 cm deep x 100 cm wide x 170 cm height

Its small size makes it ideal for workshops where space is at a premium.

It’s made entirely of stainless steel and can be backlit via its opaline white polycarbonate back, which is 5 mm thick.

The booth comes disassembled in two separate packages to reduce transport costs.

The assembly instructions are simple, and it takes just a few minutes to put together using the three tools that come supplied.

The flexible, extendible discharge pipe can be connected to a closed loop recirculation system for treating the water.

The washout booth can be backlit: it doesn’t actually have a light itself, but can be backlit via its semi-transparent back.

To do so, it’s simply necessary to attach a light source to the wall behind the booth: a neon tube, an LED light, or a simple bulb will all suffice.

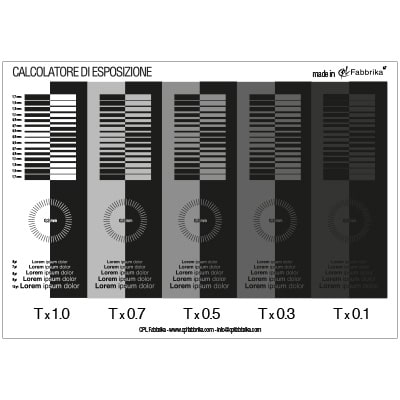

Backlighting makes it easier to check that the screen has developed correctly and to make sure that the thinner lines on the design have opened.

The booth is equipped with two stainless steel stands that can hold the frame in various positions to facilitate the washing process.

With these stands it’s also possible to use the tank for emulsifying screens, saving even more space. To do so, place the stretched screen on the stands, choose the required inclination and then apply the emulsion, this enables the scoop coater to be managed and moved with both hands,

thus making the process a little bit easier for less experienced screen printers.