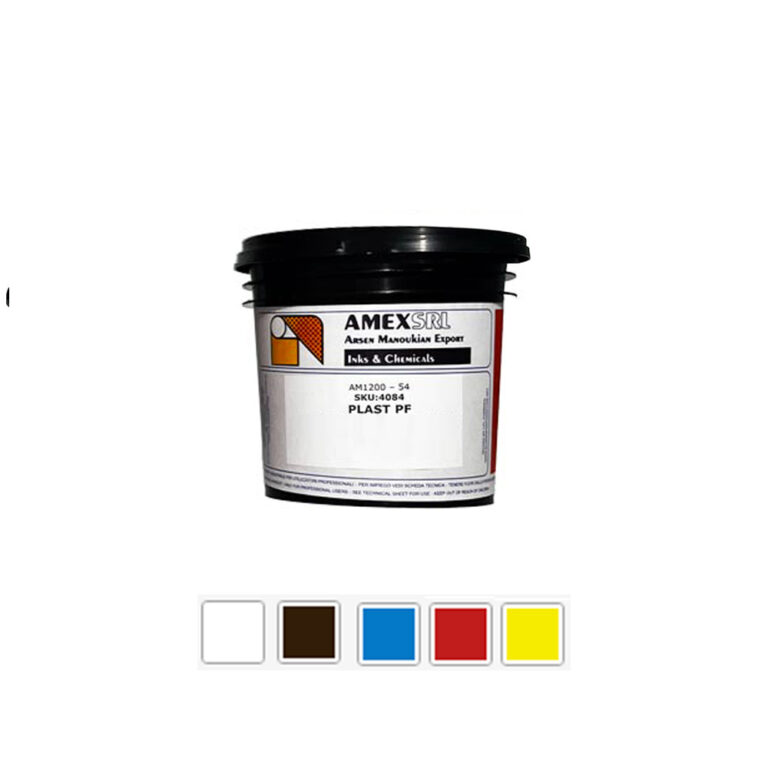

Plastisol Plast PF Amex screen printing inks are the ideal choice for professionals and textile printing enthusiasts seeking high-quality results on T-shirts, sweatshirts, and other cotton or blended garments. This ink line stands out for its exceptional opacity, enabling full and vibrant colors even on dark backgrounds, and its ease of printing, making the screen printing process smoother and more efficient.

One of the main features of Amex Plastisols is their brilliance and superior wash resistance, tested up to 60°C, ensuring your creations maintain their beauty over time. Although ready to use, it is always advisable to check the ink’s viscosity before starting to print. For optimal fluidity, it is recommended to store and use the product at an ambient temperature of around 20°C and to stir it vigorously before use, given its thixotropic nature. If necessary, viscosity can be further adjusted by gradually adding the appropriate Plastisol Additive 86, mixing thoroughly. Remember that white, due to its high pigmentation, will naturally be denser.

The Amex Plastisol range includes different options for every creative need:

Standard Colors: A wide selection for your direct prints.

Plastisol Plast PF Fluo: Fluorescent inks with high opacity and brilliance, with the significant advantage of not drying on the screen, preventing clogging issues and waste.

Plastisol Plast PF Process: A specific line compuesto of 4 base colors (CMYK) plus a cutting paste, perfect for creating detailed and nuanced four-color process prints.

Curing Plastisol inks can be achieved through various methods:

Flash Cure Unit/Conveyor Dryer: at 160°C for approximately 1 minute.

Heat Press: at 180°C for 90 seconds (maintaining a distance of about 1 cm between the platen and the fabric), or at 180°C for 70-80 seconds with a 10 mm gap between the platens, a practical method that does not require the use of parchment paper or other intermediaries. The heat press offers precise and consistent control of time and temperature, ensuring repeatable results.

Oven: at 160°C for 2-3 minutes.

It is possible to mix Plastisols to obtain custom shades, although for specific, opaque colors, it is advisable to opt for ready-to-use shades to avoid dull or weak results.

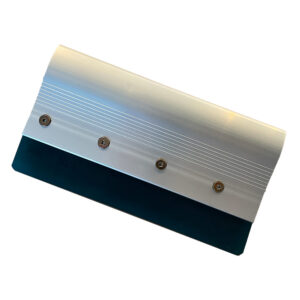

After use, cleaning screen printing tools is simple and quick: just use the specific Screen Wash Solvent.

Choose Amex Plastisol inks to bring professional, durable, and visually striking textile prints to life.

Synthetic Evaluation:

Amex Plastisol inks are a versatile and high-performing solution for screen printing on textiles. They offer an excellent balance of ease of use, final result quality, and durability. The availability of specific ranges like Fluo and Process makes them suitable for a wide variety of creative and professional projects.

Pros:

High opacity and color brilliance.

Excellent wash resistance.

Easy viscosity management.

Fluo range does not dry on the screen, improving efficiency.

Availability of the Process (CMYK) line.

Versatility in curing methods.

Good overall printability.