– What is this emulsion for?

QLT universal emulsion is particularly suitable for exposing screens on which Plastisol and Solvent-based inks are to be used.

Our tests have shown that the maximum output with water-based inks is approximately 200 prints.

But it’s still a Universal Screen Printing Emulsion, suitable for all ink types.

– Is it necessary to add Diazo?

No, for this type of emulsion adding Diazo is not necessary.

Therefore it is considered a ready-for-use emulsion.

If kept refrigerated at 5°C, it can last up to 90 days.

In any case, it must be stored in a dark location and in a sealed container.

– What stripper can be used to remove it?

This type of emulsion can be effectively removed from the screen using the Quasar Liquid Stripper.

– What light needs to be used for exposing the screen?

QLT emulsion can be exposed with both white and UV light

What procedure should I follow to make the best use of QLT Screen Printing Emulsion?

To successfully use QLT Screen Printing Emulsion (and any other emulsion in general) we suggest the following procedure.

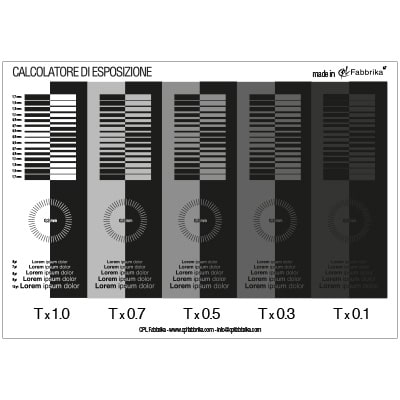

– Exposure lamp to frame distance. The ideal distance between the exposure lamp and the frame is 1.5 m, but in my opinion 1 m is a good enough compromise.

I’d try an exposure time of 4 minutes.

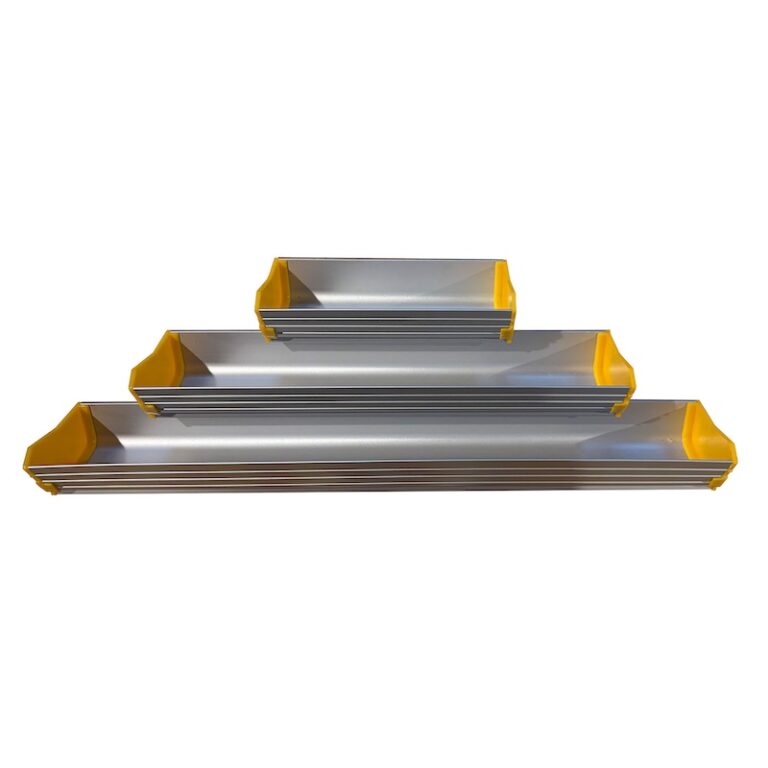

– Emulsion thickness. The emulsion thickness is normally measured in micrometers, not in millimetres, and the final thickness of the emulsified screen must more or less correspond to the thickness of the mesh: in fact, the emulsion actually sits between the threads of the mesh, meaning the external layer is really thin.

To achieve this, the final pass with the scoop coater should be done backwards, in so doing, and by applying moderate pressure, it’s possible to remove the excess emulsion and gather it into the scoop coater.

– A thin layer of emulsion offers a number of advantages:

1) whilst drying, the emulsion doesn’t drip;

2) the thickness is more uniform, it isn’t impacted so much by the operator’s dexterity, therefore the exposure times are easier to control;

3) if some of the lines in the design are quite fine, the light doesn’t harden the emulsion under them because the light doesn’t “pass through” the film.

Indeed, I think that the problem you experienced (fine lines not being visible) is due to an excessively thick layer of emulsion, an excessive exposure time due to the 35 cm distance from the exposure lamp, and perhaps also the fact that a laser toner doesn’t produce a black that’s sufficiently opaque on the film.

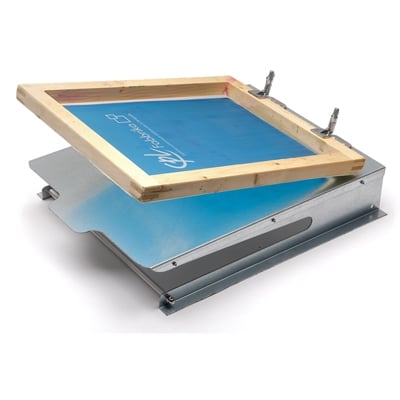

– After 30 minutes of washing the emulsion starts to have issues, it effectively melts or, if it’s too thick, it comes off the screen in lumps.

Preparing a screen printing frame in water should take no longer than 4-5 minutes.

If, after this period of time, nothing happens, it means something’s wrong.