Production capacity: about 200 garments / hour

Maximum fabric temperature: about 190 ° c

Maximum consumption: kw 7,5 max

Conveyor belt width mm 600

Total width 800 mm

Tunnel length 1500 mm

Total length 2700 mm

Smoke outlet pipe diameter mm 80 weight kg 200

The “Small” electric screen printing oven is designed to dry both plastic and water-based inks; the former are polymerized using dark radiant panels, while the latter are dried thanks to a forced air circulation

Lateral drying: the oven is also equipped with side drying using a quartz lamp.

This type of drying is essential for the numerous objects that are printed on the side (hats, ashtrays, pencil holders etc.)

Adjustment of the useful height of the tunnel:

To obtain excellent drying results it is important that the surface to be dried is at the right distance from the radiant panel (5-7cm). The useful height is adjustable from 8 to 25

Temperature regulation:

The advantage of dark radiant panels is given by the possibility of regulating the working temperature of the panels themselves by positioning the probe inside.

It follows that the accuracy of the temperature of use is not affected by external factors (variation of the intensity of the electric current)

Insulation:

Particularly accurate. The whole structure of the oven remains at a low temperature, it does not heat the working environment

Exaust:

The oven is equipped with an aspirator for the expulsion of the processing fumes.

The work environment remains completely “Clean”

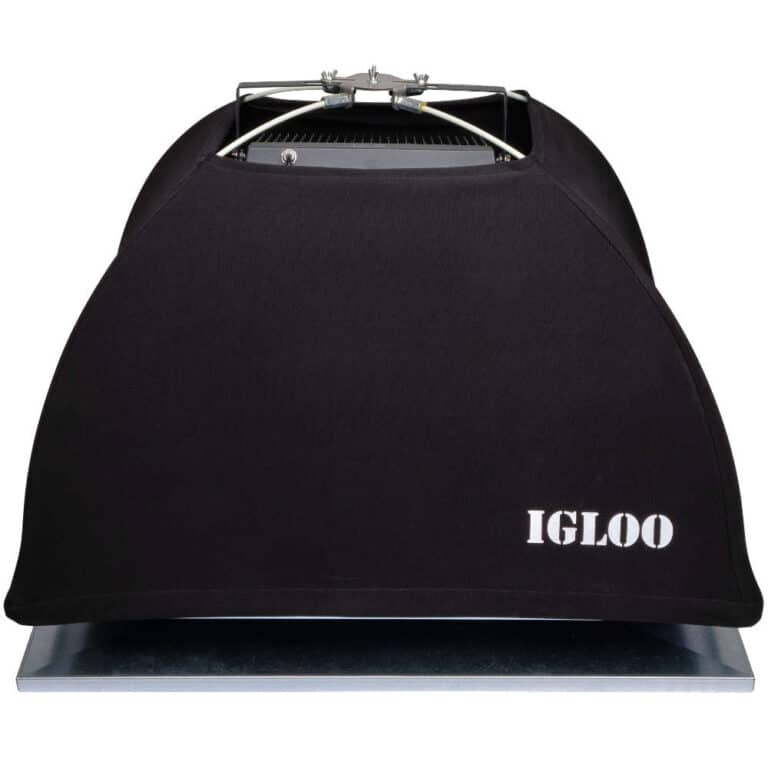

Cooling:

The piccolo electric oven is equipped with a cooling hood to lower the temperature of the dried material

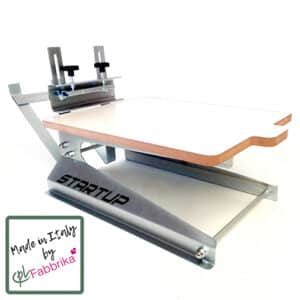

Conveyor belt:

It is made with special fabrics that resist up to 200 ° c., the tensioning system allows a long life of the belt.

Economic advantages:

All the electric current is transformed into heat.

Rapid rise in temperature thanks to the low thermal inertia of the radiant panels which also offer a high performance that is constant over time

Production advantages:

An adjustable forced circulation of hot air allows perfect drying even of water-based inks.

By bringing the panel very close to the fabric, losses due to “Convection” are reduced.

The regulation of the temperature of the radiant panels allows more precision in the work; the “Long waves” are the most suitable to be absorbed by the inks.

There is no need to vary the working temperature often, as light or dark inks cure at the same temperature. Teflon glass conveyor belt

Belt speed adjustable with electric variator. Height adjustment of radiant panels from 50 to 250 mm.

Price shown: including packaging